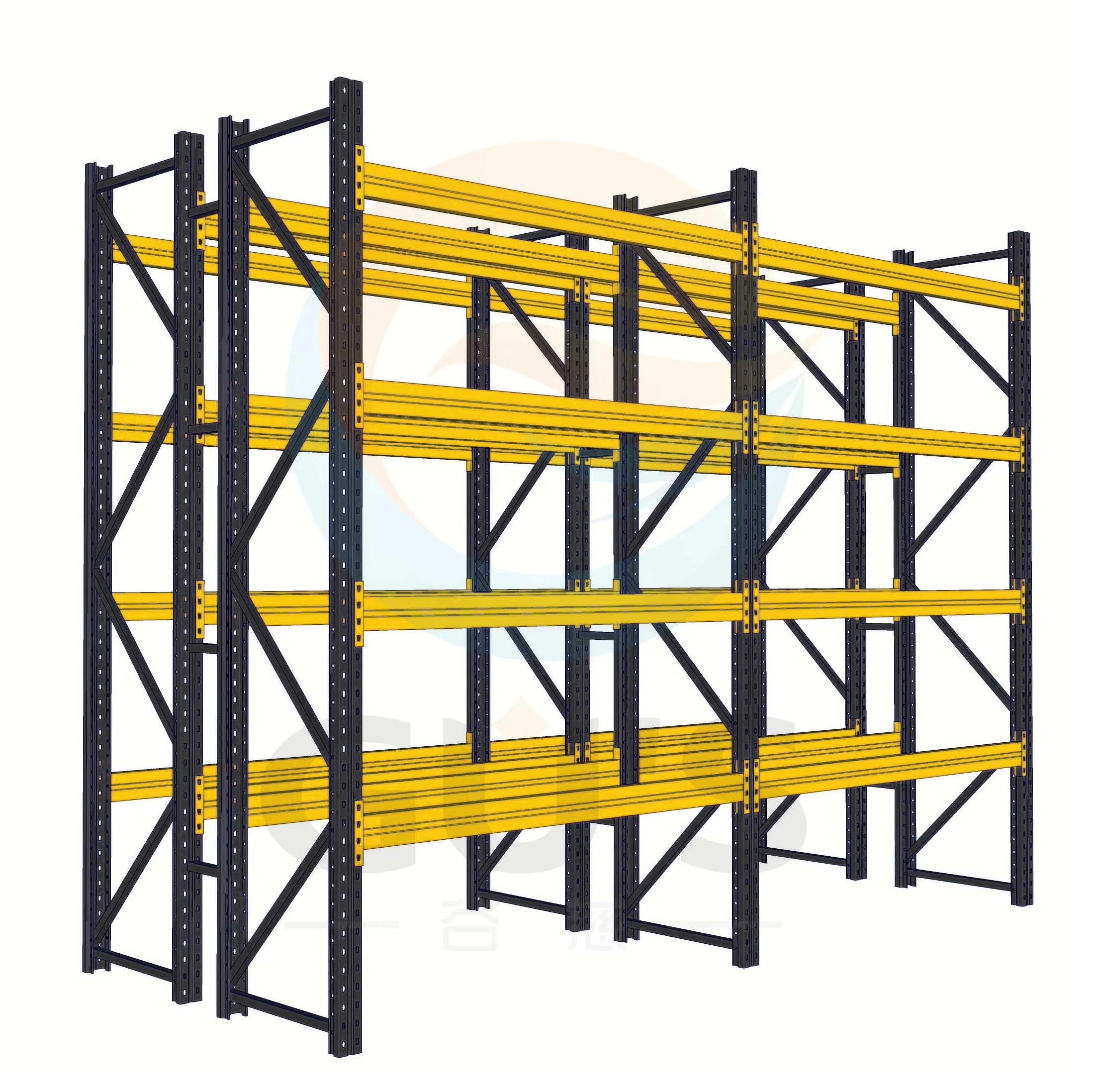

automated pallet racking system

An automated pallet racking system represents a cutting-edge solution in modern warehouse management, combining advanced robotics and intelligent software to revolutionize storage and retrieval operations. This sophisticated system utilizes computer-controlled machines, including automated storage and retrieval systems (AS/RS), to handle palletized goods with precision and efficiency. The system operates through a network of vertical lifts, horizontal transporters, and computerized control systems that work in harmony to manage inventory movement. At its core, the system features high-density storage configurations that maximize vertical space utilization, while automated shuttles and cranes navigate through narrow aisles to access stored items. The integration with warehouse management systems (WMS) enables real-time inventory tracking, automated order fulfillment, and systematic storage allocation. These systems can operate in various environments, from refrigerated warehouses to standard storage facilities, and can handle different pallet sizes and weights. The technology incorporates safety features such as collision avoidance systems, load sensors, and emergency stop mechanisms to ensure secure operations. Applications span across industries, including manufacturing, distribution, retail, and e-commerce, where high-volume storage and rapid retrieval capabilities are essential for maintaining competitive advantages in the market.