pallet racking brands

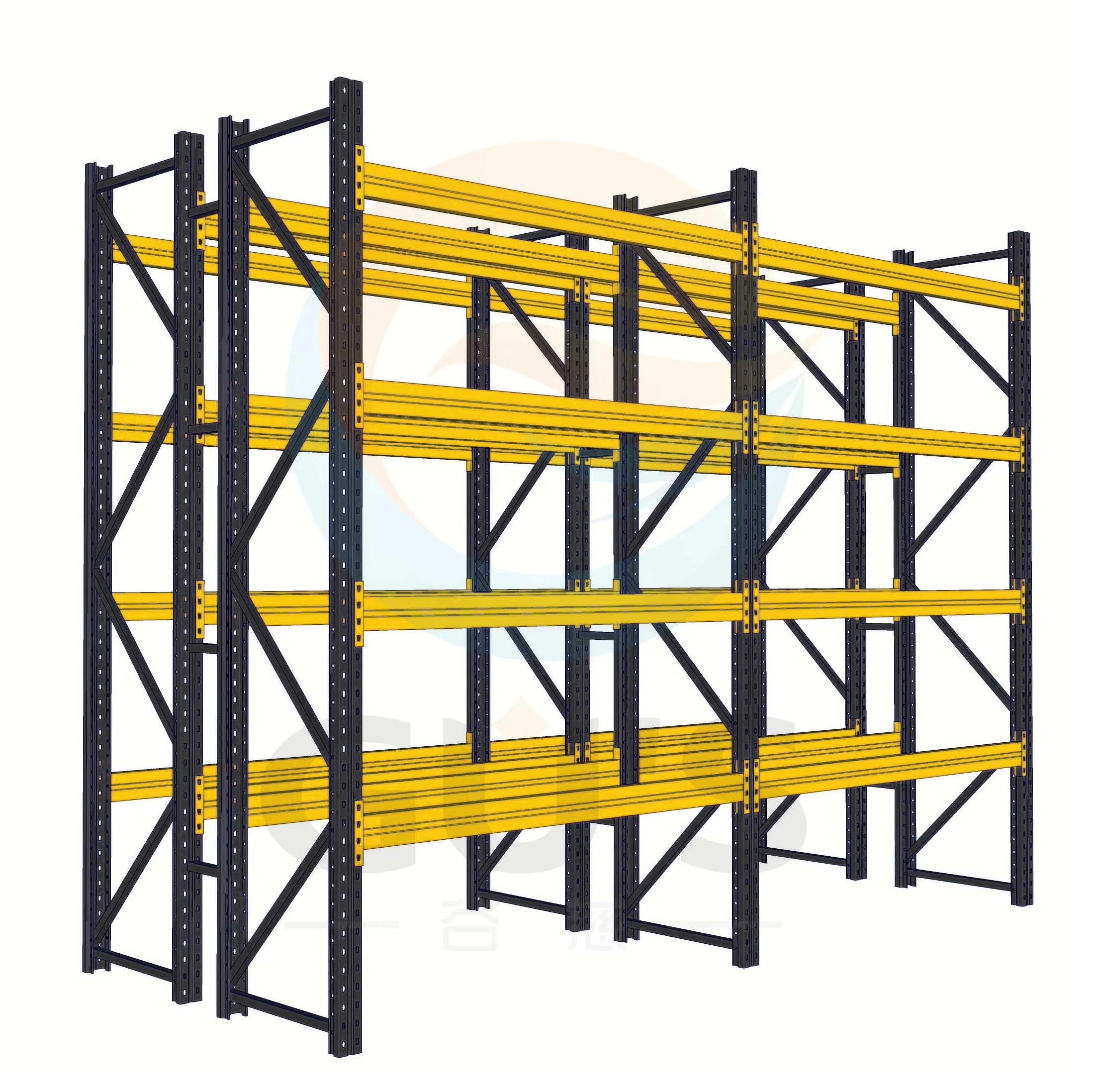

Pallet racking brands represent the cornerstone of modern warehouse management systems, offering sophisticated storage solutions that maximize vertical space utilization and enhance operational efficiency. Leading manufacturers like Interlake Mecalux, SSI Schaefer, and Dexion have established themselves as industry pioneers by developing innovative racking systems that incorporate advanced safety features and adaptable configurations. These systems typically feature high-grade steel construction, precision engineering, and modular designs that accommodate various load capacities and pallet sizes. Modern pallet racking solutions integrate seamlessly with warehouse management software, enabling real-time inventory tracking and optimization. The systems commonly include selective racking, drive-in racking, push-back racking, and dynamic flow configurations, each designed to meet specific storage requirements and material handling needs. Advanced coating technologies provide superior corrosion resistance, while sophisticated beam locking mechanisms ensure structural integrity and workplace safety. These brands also offer specialized solutions for cold storage, seismic zones, and automated warehouses, demonstrating their commitment to addressing diverse industrial applications.