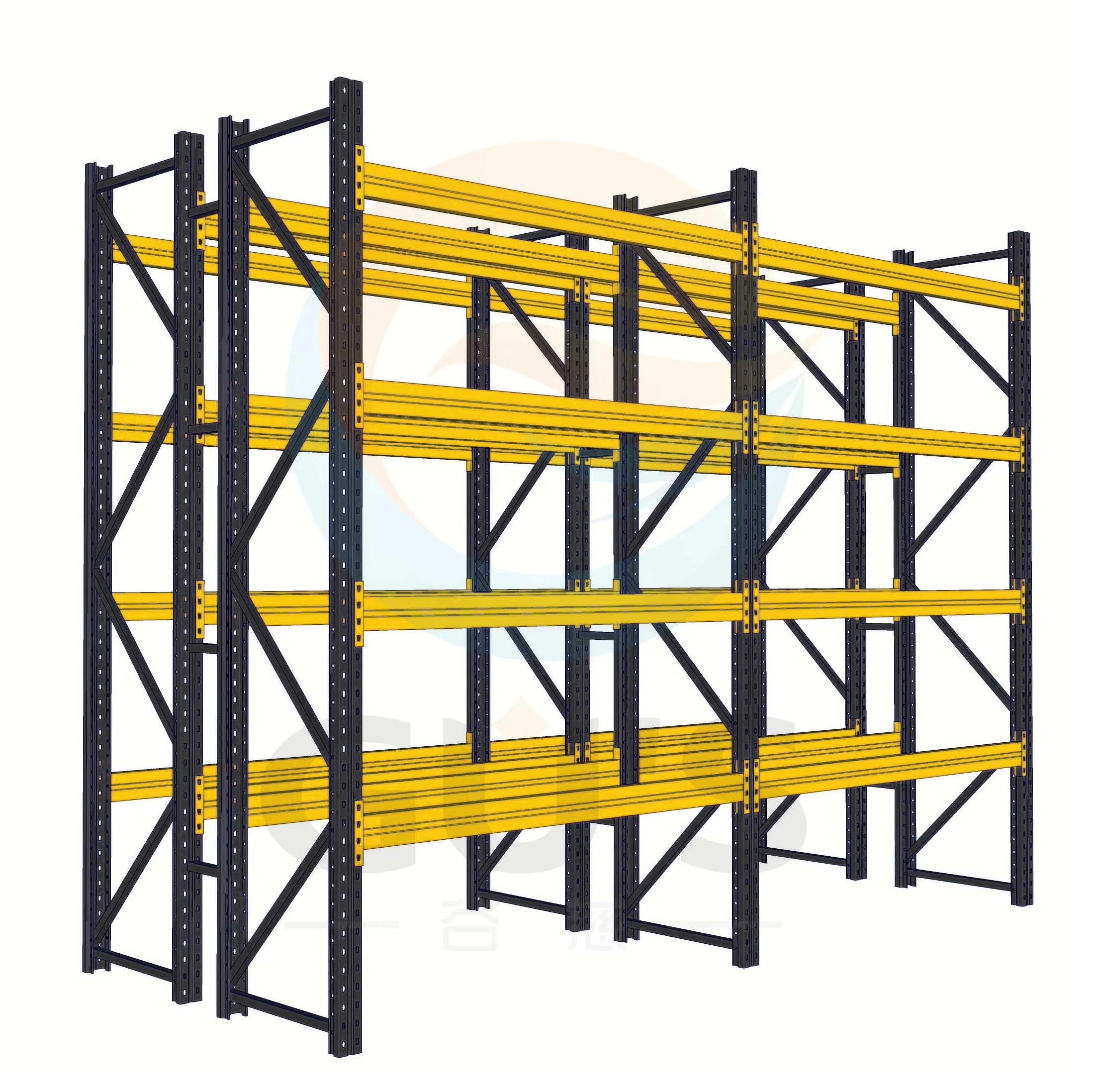

stackable steel racks

Stackable steel racks represent a revolutionary storage solution that combines durability, flexibility, and space optimization. These robust storage systems are engineered using high-grade steel components, ensuring maximum strength and longevity while maintaining a relatively lightweight structure. The modular design allows for vertical expansion, making it possible to adapt to changing storage needs without requiring additional floor space. Each rack features precision-welded joints and reinforced support points that can withstand substantial weight loads, typically ranging from 500 to 2000 pounds per level depending on the specific model. The racks incorporate adjustable shelf levels that can be modified in small increments, typically 1-2 inches, allowing for customization based on stored items. Advanced powder coating technology provides superior resistance to corrosion, scratches, and daily wear, extending the product lifespan significantly. The installation process utilizes a tool-less assembly system with interlocking components, enabling quick setup and reconfiguration as needed. These racks are compatible with various material handling equipment, including forklifts and pallet jacks, facilitating efficient loading and unloading operations.