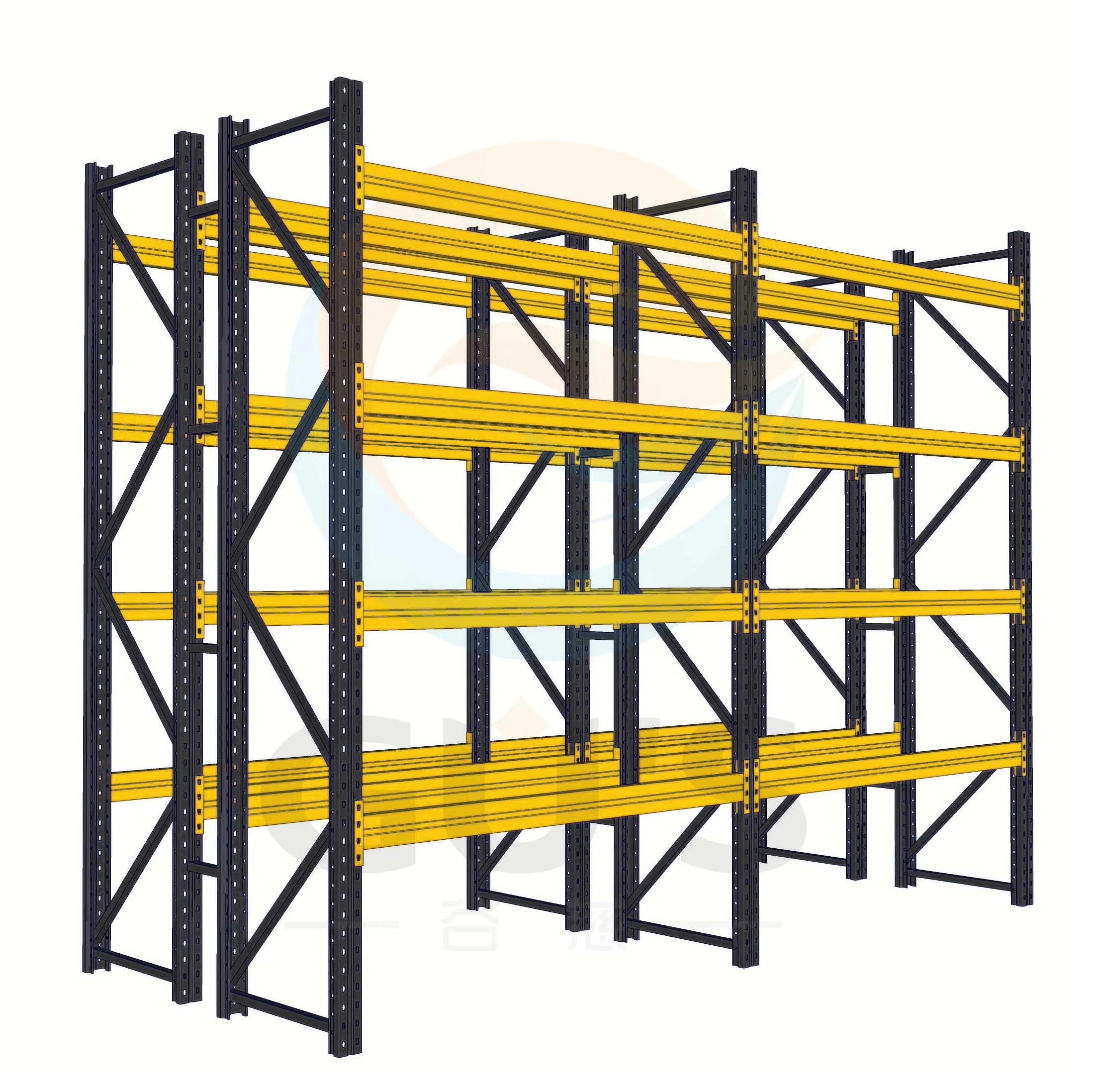

stacking racks for warehouse

Stacking racks for warehouses represent an essential storage solution designed to maximize vertical space utilization while ensuring efficient inventory management. These robust storage systems feature adjustable levels and modular configurations that can be customized to accommodate various load sizes and weights. The racks are engineered with high-grade steel and precise welding techniques, offering exceptional durability and stability for long-term use. Modern stacking racks incorporate advanced safety features, including load capacity indicators, anti-collapse systems, and protective guards, ensuring workplace safety compliance. They utilize innovative beam-to-upright connections that allow for quick assembly and reconfiguration as storage needs evolve. The systems can be integrated with automated storage and retrieval systems (AS/RS), featuring compatible guide rails and precise positioning mechanisms. These racks support various handling equipment, from traditional forklifts to advanced picking robots, enhancing operational efficiency. The versatile design accommodates different storage methods, including selective, drive-in, push-back, and flow rack systems, making them suitable for various warehouse operations and inventory management strategies.