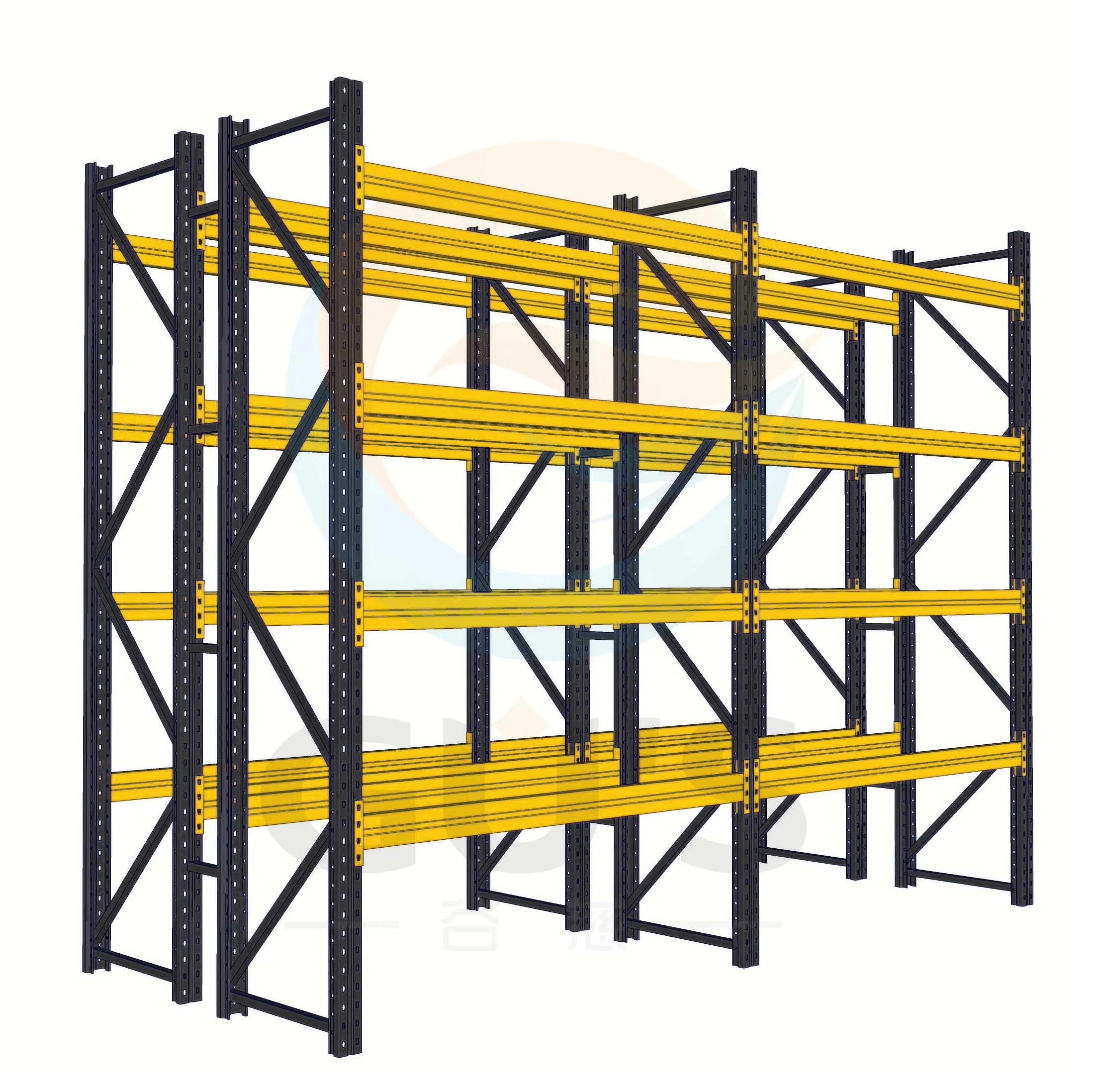

vertical storage solutions for warehouses

Vertical storage solutions represent a revolutionary approach to warehouse management, maximizing vertical space utilization while minimizing floor space requirements. These sophisticated systems incorporate automated storage and retrieval mechanisms (AS/RS) that operate within vertical columns, effectively utilizing building height to create additional storage capacity. Modern vertical storage solutions feature advanced computer-controlled systems that enable precise inventory tracking, rapid access to stored items, and efficient space utilization. These systems typically include vertical lift modules (VLMs), vertical carousels, and multi-level storage structures that can extend up to facility ceiling heights. The technology integrates seamlessly with warehouse management systems (WMS), providing real-time inventory updates and automated picking processes. Applications span across various industries, from manufacturing and retail to healthcare and automotive sectors, where space optimization and quick access to inventory are crucial. These systems can handle diverse load types, from small parts to palletized goods, with built-in safety features and ergonomic design considerations that enhance worker productivity and reduce workplace injuries. The integration of IoT sensors and smart technology enables predictive maintenance and performance optimization, ensuring consistent operation and minimal downtime.