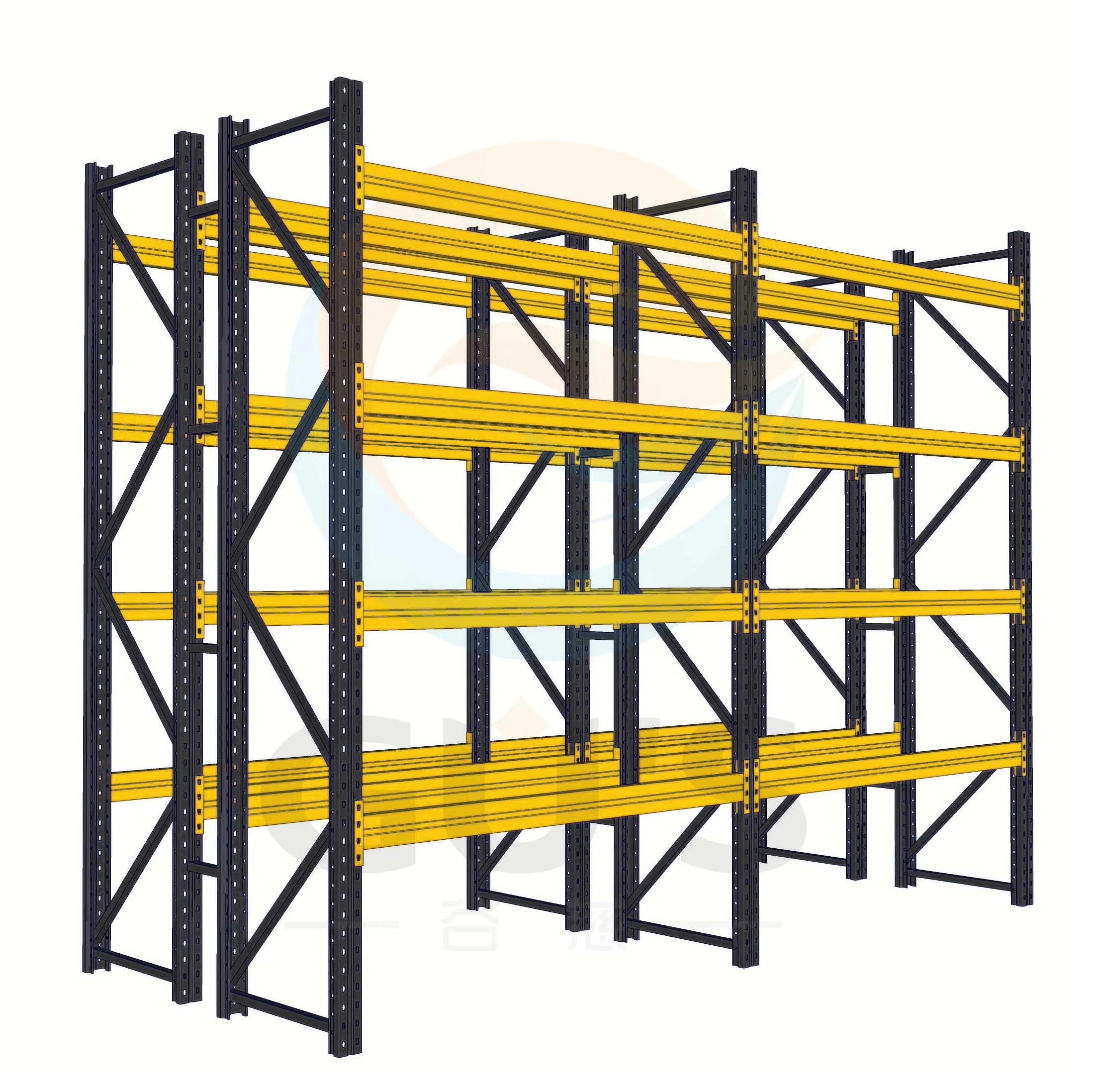

warehouse logistics solutions

Warehouse logistics solutions represent a comprehensive approach to optimizing storage, inventory management, and distribution operations. These solutions integrate advanced technologies and methodologies to streamline warehouse processes, ensuring efficient material handling and order fulfillment. At their core, warehouse logistics solutions encompass automated storage and retrieval systems (AS/RS), warehouse management systems (WMS), and intelligent inventory tracking mechanisms. The technology infrastructure includes real-time tracking capabilities through RFID and barcode systems, automated guided vehicles (AGVs) for material transport, and sophisticated software platforms that coordinate all warehouse activities. These systems work in concert to maintain accurate inventory levels, optimize space utilization, and reduce operational costs. The solutions are highly adaptable, serving various industries from retail and e-commerce to manufacturing and distribution. They enable businesses to achieve greater accuracy in order processing, reduce human error, and maintain consistent service levels. Modern warehouse logistics solutions also incorporate predictive analytics and machine learning algorithms to forecast demand patterns and optimize stock levels. This comprehensive approach ensures seamless integration of all warehouse operations, from receiving and putaway to picking, packing, and shipping.