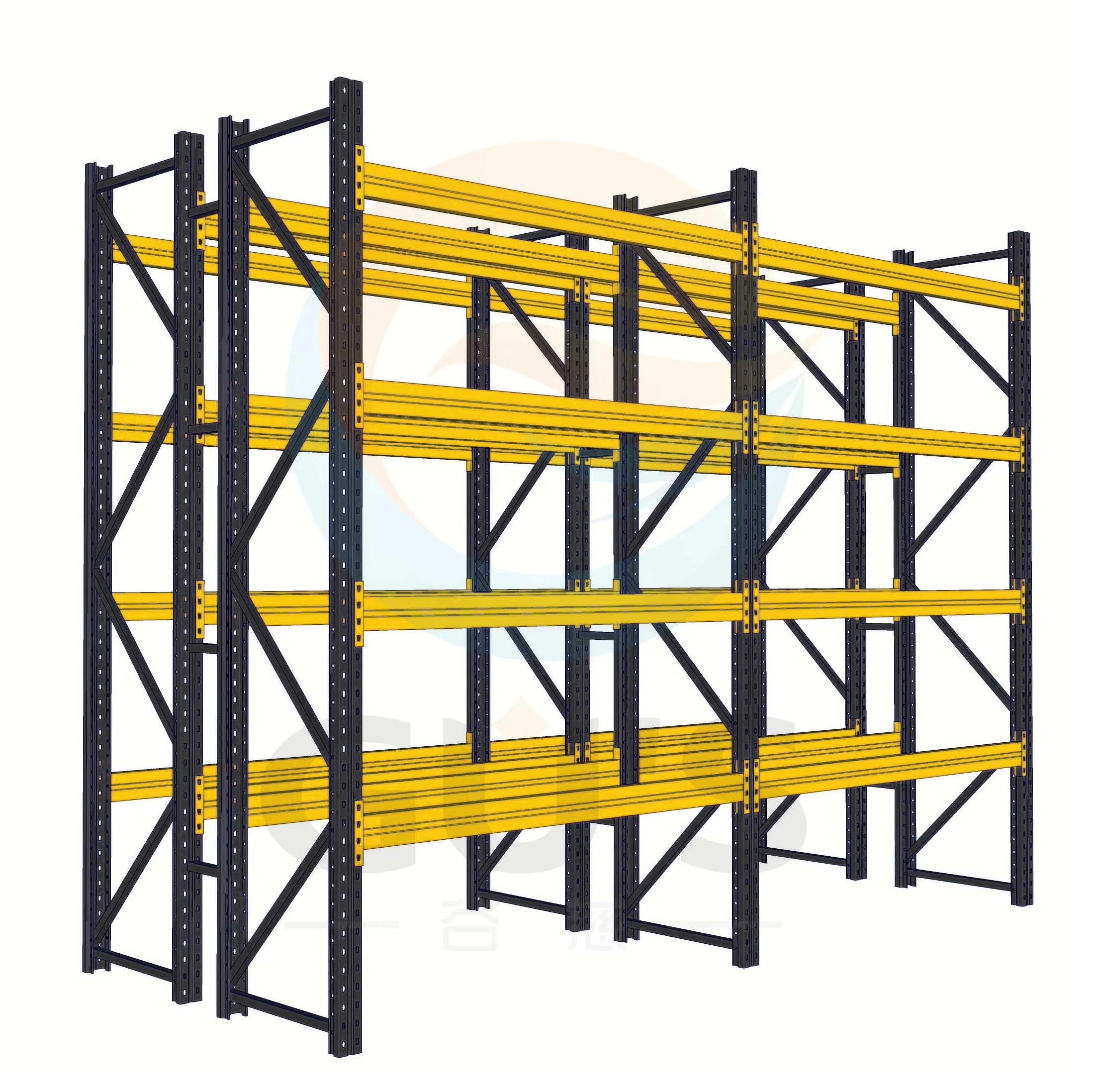

warehouse racking solutions

Warehouse racking solutions represent cutting-edge storage systems designed to maximize vertical space utilization and streamline inventory management operations. These sophisticated storage solutions incorporate advanced structural engineering principles to create robust, flexible, and scalable storage frameworks that can accommodate various load capacities and product dimensions. The systems typically feature adjustable beam levels, multiple tier options, and specialized accessories that can be customized to meet specific storage requirements. Modern warehouse racking solutions integrate seamlessly with automated storage and retrieval systems (AS/RS), incorporating smart sensors for load monitoring and sophisticated inventory tracking capabilities. They are engineered to optimize warehouse space utilization, with options including selective racking for direct access to all pallets, drive-in systems for high-density storage, and dynamic flow racks for efficient inventory rotation. These systems also include advanced safety features such as impact protection, load indicators, and anti-collapse mechanisms, ensuring both operator safety and product security. The versatility of these solutions makes them ideal for various industries, including retail distribution, manufacturing, e-commerce fulfillment, and cold storage facilities.