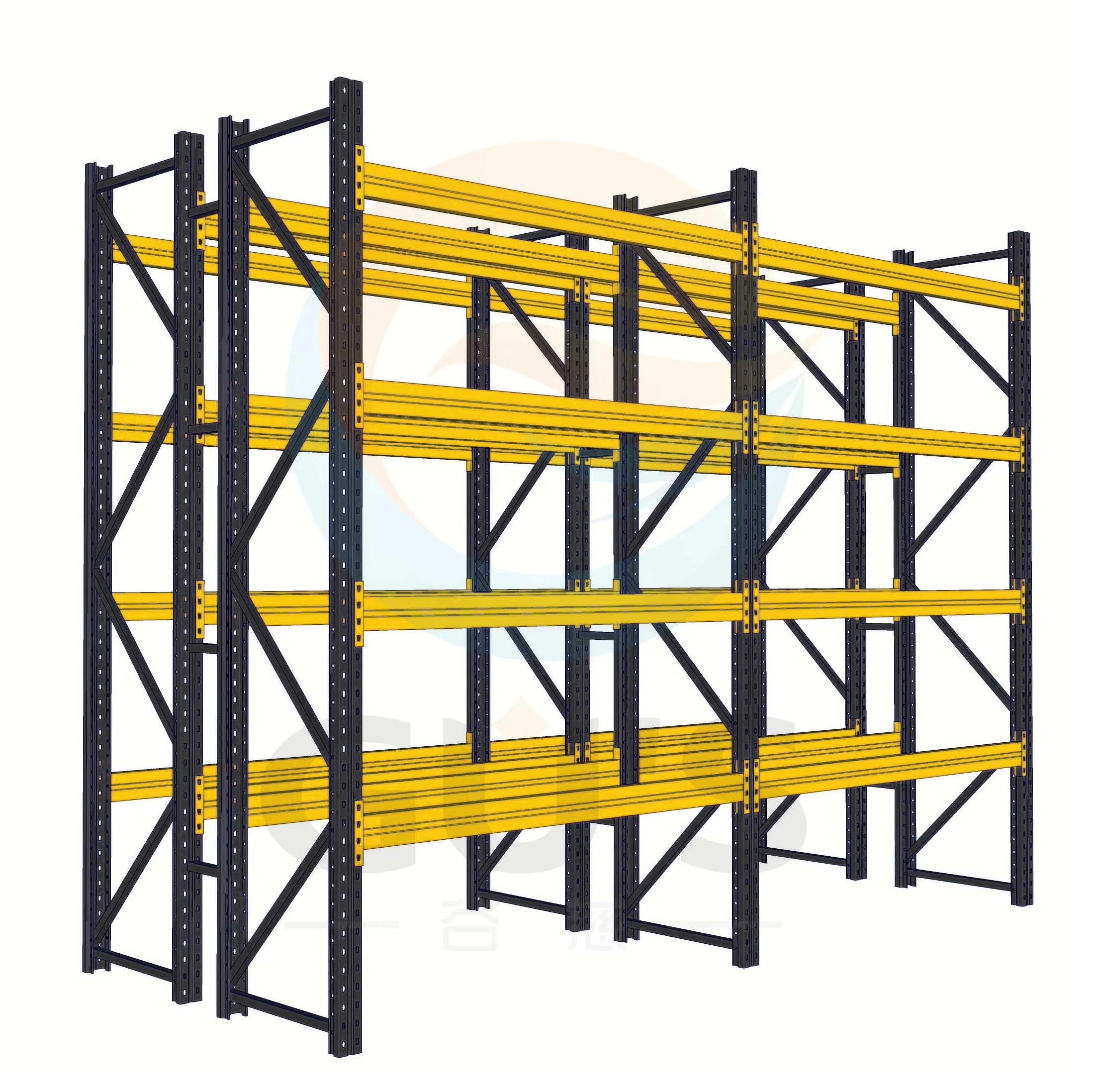

custom pallet racking

Custom pallet racking represents a sophisticated storage solution designed to maximize warehouse efficiency and space utilization. These systems are engineered to precise specifications, accommodating various pallet sizes, weights, and handling requirements specific to each facility's needs. The system comprises adjustable beams and uprights, allowing for flexible configuration of storage levels and bay widths. Advanced materials and structural engineering ensure optimal load-bearing capacity while maintaining system integrity. Modern custom pallet racking incorporates safety features such as impact protection, load indicators, and anti-collapse mechanisms. The systems can be integrated with automated handling equipment, including forklifts and automated storage and retrieval systems (AS/RS). Technological innovations include RFID tracking capabilities, smart sensors for load monitoring, and integration with warehouse management systems. These racks are suitable for various industries, from retail and manufacturing to cold storage and distribution centers, offering versatility in storage solutions while maintaining strict compliance with international safety standards.