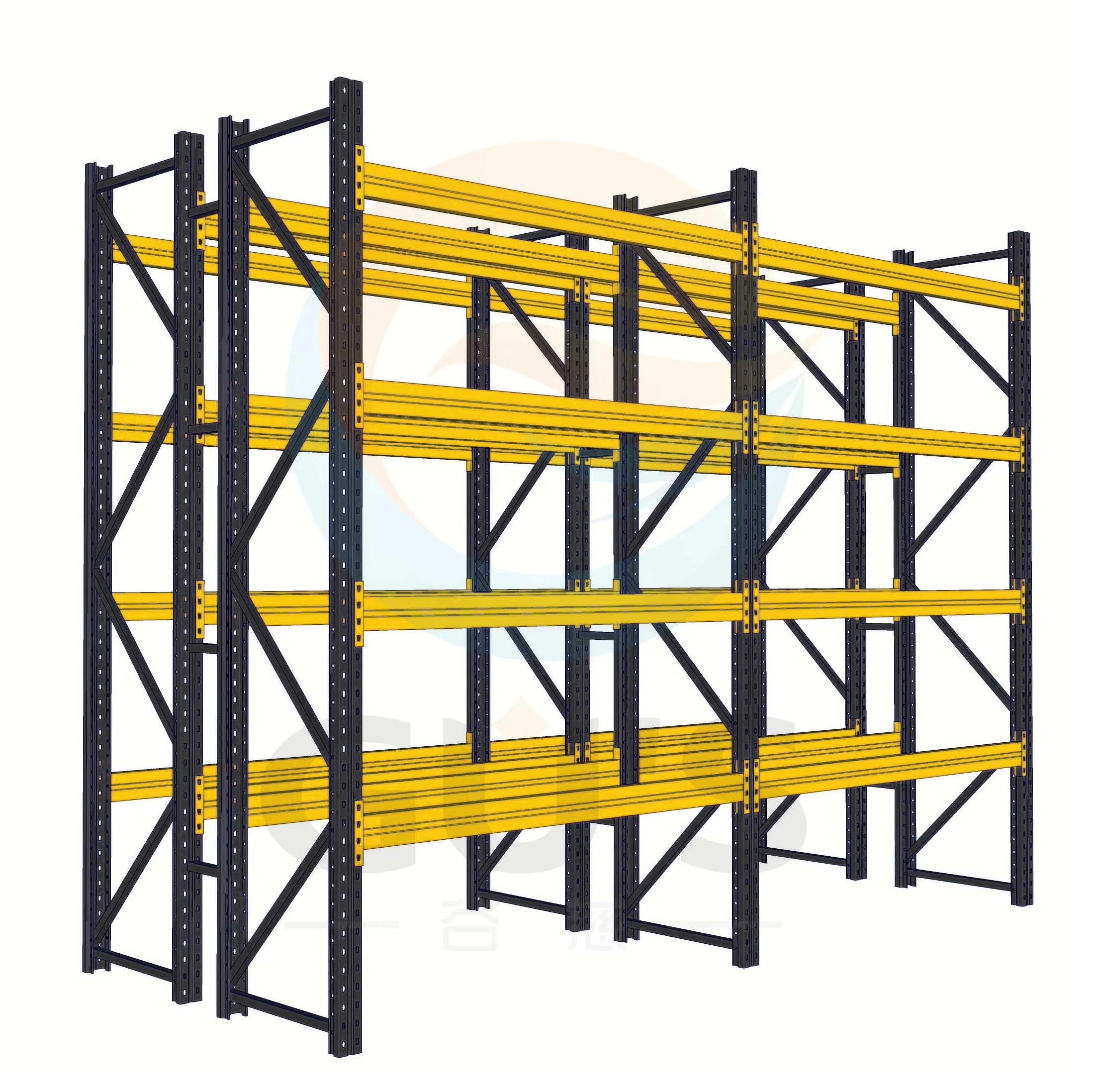

Customizable Configuration Options

Rack stacking systems offer unparalleled flexibility through their highly customizable design options. The modular construction allows for easy reconfiguration to accommodate changing storage needs and product dimensions. Multiple shelf types, including selective, drive-in, and push-back configurations, can be incorporated into a single system to optimize storage for different product categories. Adjustable beam levels enable precise height optimization for various load sizes, while specialized accessories such as wire mesh decking, drum cradles, and coil supports cater to specific storage requirements. The system can be equipped with various access options, from standard forklift operations to automated storage and retrieval systems, ensuring compatibility with existing warehouse equipment and workflows.