mezzanine floor factory

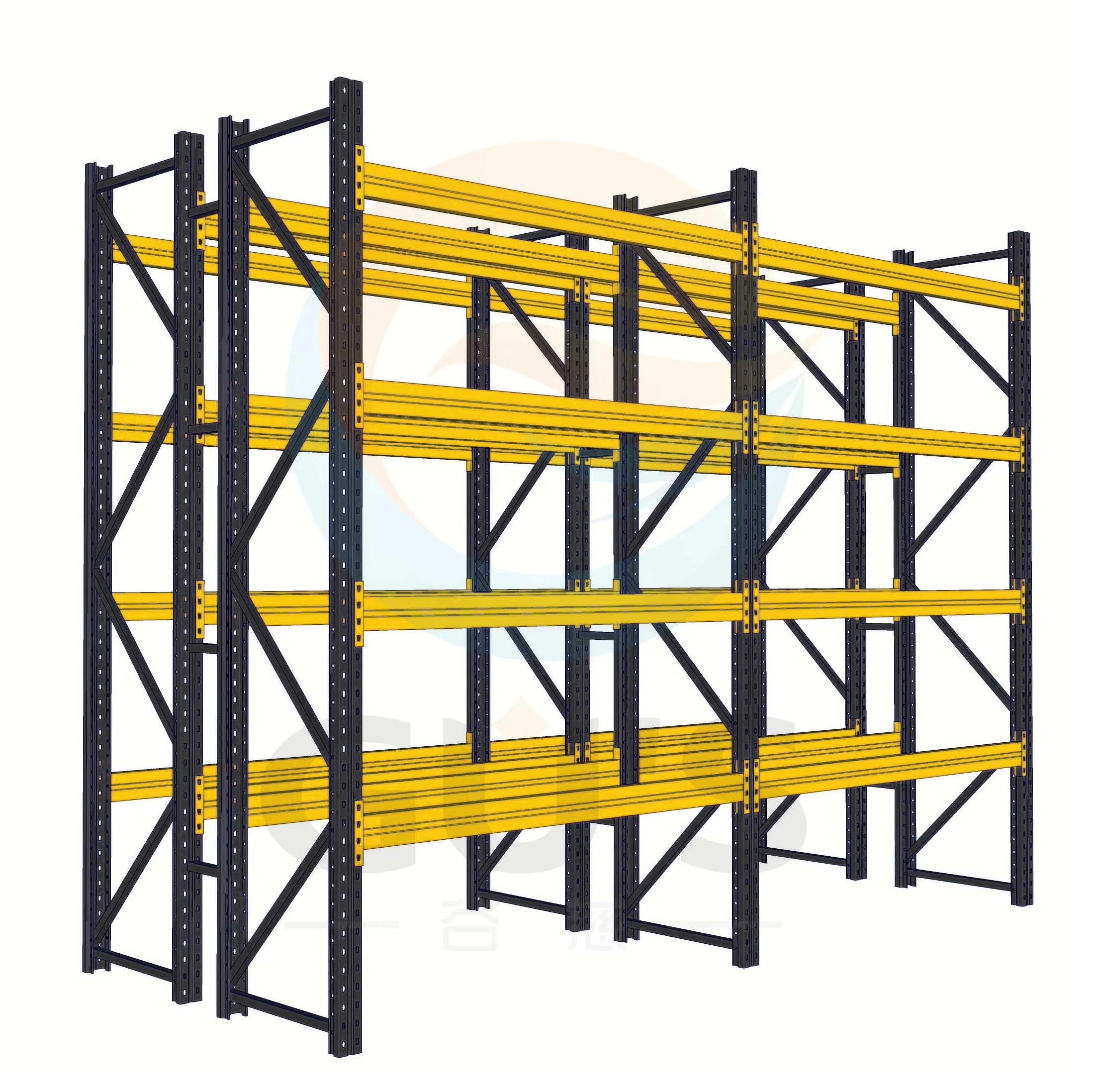

A mezzanine floor factory specializes in designing, manufacturing, and installing custom-built intermediate floors that maximize vertical space utilization in industrial and commercial settings. These facilities employ state-of-the-art engineering processes and advanced manufacturing equipment to produce high-quality structural components that seamlessly integrate into existing buildings. The factory utilizes precision cutting technology, automated welding systems, and quality control measures to ensure each component meets strict safety and durability standards. The production process incorporates modern CAD/CAM systems for accurate design implementation, while specialized coating applications provide enhanced protection against wear and environmental factors. The facility's capability extends to producing various mezzanine systems, including free-standing structures, integrated platforms, and multi-tier installations, all customizable to specific load requirements and spatial configurations. The factory maintains dedicated areas for material storage, fabrication, finishing, and quality testing, ensuring efficient workflow and consistent product quality. Advanced logistics systems manage inventory and coordinate timely delivery to construction sites, while experienced technical teams provide installation support and maintenance guidance.