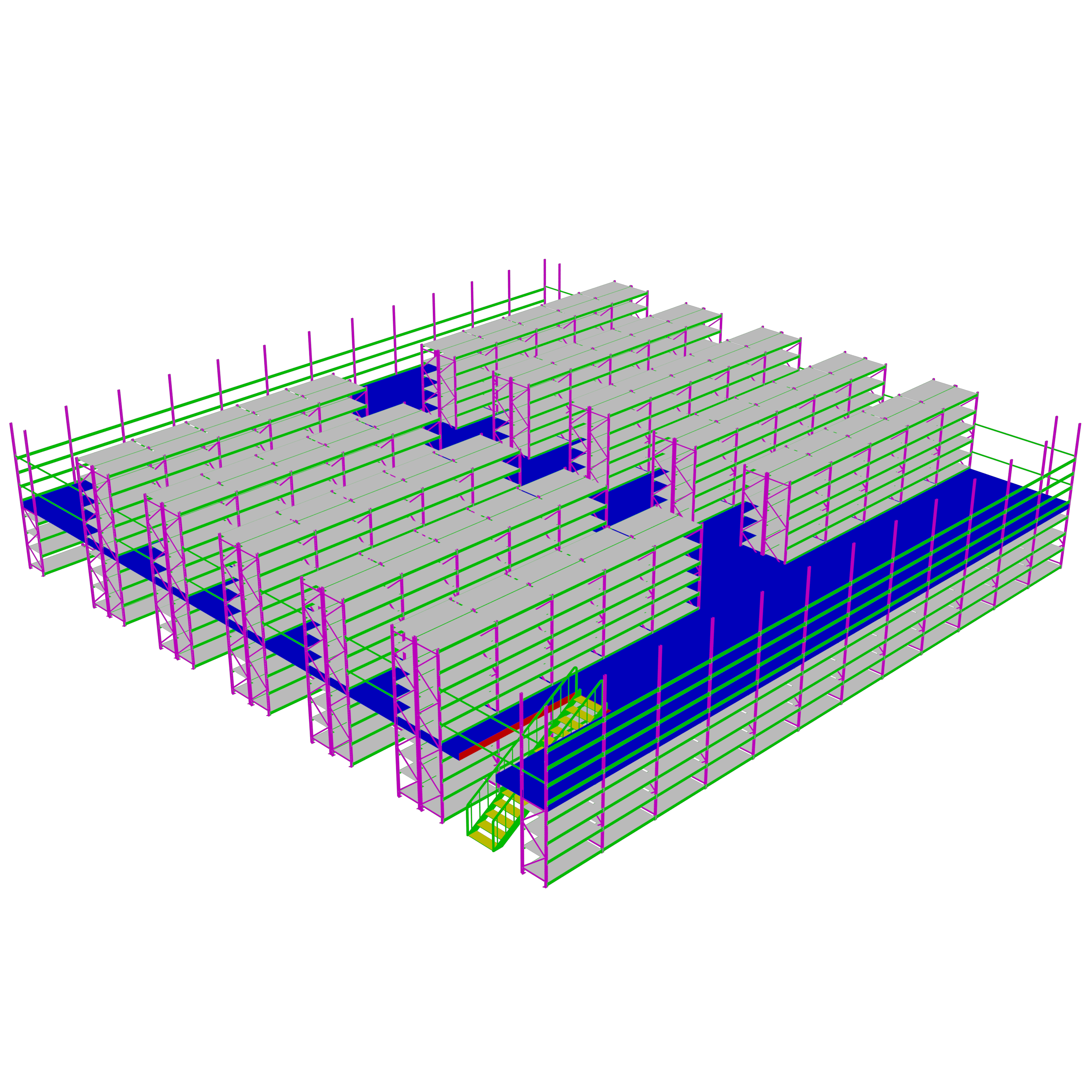

Proper maintenance of industrial storage systems is essential for warehouse safety and operational efficiency. Mezzanine racks represent a significant investment in vertical storage capacity, making their longevity and structural integrity paramount concerns for facility managers. These multi-level storage solutions require systematic care to ensure they continue performing optimally while maintaining the highest safety standards. Understanding the fundamentals of maintenance protocols can extend the service life of these systems by decades while preventing costly repairs and dangerous structural failures.

The complexity of modern warehouse operations demands that storage infrastructure operates without interruption. Mezzanine racks support substantial weight loads across multiple levels, making their maintenance critical for both productivity and personnel safety. Regular maintenance protocols not only preserve the structural integrity of these systems but also help identify potential issues before they escalate into major problems. Implementing comprehensive maintenance strategies ensures compliance with safety regulations while maximizing return on investment through extended equipment life cycles.

Daily visual inspections form the cornerstone of effective mezzanine rack maintenance programs. Trained personnel should examine all visible components including uprights, beams, diagonal braces, and connection points for signs of damage, wear, or misalignment. These inspections should focus on identifying bent or twisted members, loose bolts, damaged welds, and any visible cracks in the structural elements. Documentation of findings through standardized checklists ensures consistency and provides valuable historical data for trend analysis.

The inspection process should include checking floor conditions around the rack base, looking for signs of settlement or damage to anchor bolts. Personnel conducting these assessments must be trained to recognize subtle signs of structural stress that could indicate developing problems. Any irregularities discovered during daily inspections should be immediately reported and addressed according to established safety protocols. Regular photographic documentation can help track the progression of minor issues and provide evidence for warranty claims or insurance purposes.

Monitoring load distribution across mezzanine rack levels requires ongoing attention to weight placement and storage patterns. Uneven loading can create dangerous stress concentrations that compromise structural integrity over time. Warehouse personnel should be trained to recognize proper loading techniques and understand the importance of distributing weight evenly across beam spans. Regular verification of load capacities helps prevent overloading situations that could lead to catastrophic failure.

Implementing weight monitoring systems provides real-time data about loading conditions throughout the facility. These systems can include load cells, strain gauges, or digital weight indicators that alert operators when loads approach maximum capacity limits. Establishing clear protocols for load placement and removal ensures that mezzanine racks operate within their designed parameters while maintaining optimal safety margins.

The structural framework of mezzanine racks requires systematic maintenance to preserve load-bearing capacity and prevent premature deterioration. Regular cleaning of beam surfaces removes accumulated debris and allows for thorough inspection of connection points and potential stress concentrations. Steel components should be checked for signs of corrosion, particularly in environments with high humidity or chemical exposure. Protective coatings may require periodic renewal to maintain their effectiveness against environmental factors.

Beam deflection measurements provide valuable insights into structural performance over time. Establishing baseline measurements during initial installation creates reference points for ongoing monitoring programs. Any changes in deflection patterns could indicate developing structural issues that require immediate attention. Regular torque verification of connection bolts ensures that joints remain properly secured and can transfer loads effectively throughout the system.

Mezzanine rack decking systems require specialized attention due to their role in distributing loads and providing safe working surfaces. Wire mesh decking should be inspected for damaged or missing sections that could create safety hazards or allow stored items to fall through. Solid steel decking requires checking for warping, cracking, or excessive wear that might compromise its load-bearing capacity. Any damaged decking components should be replaced immediately to maintain system integrity.

Regular cleaning of decking surfaces prevents accumulation of debris that could interfere with proper drainage or create slip hazards for personnel. Special attention should be paid to areas where spills commonly occur, as chemical contamination can accelerate corrosion processes. Maintaining proper clearances between decking panels allows for thermal expansion while preventing binding that could create stress concentrations in the supporting framework.

Fall protection systems integrated with mezzanine racks require regular inspection and maintenance to ensure personnel safety during warehouse operations. Safety railings, toe plates, and gate systems must be checked for proper attachment, structural integrity, and compliance with current safety standards. Loose or damaged components should be repaired or replaced immediately to maintain continuous protection for workers accessing elevated storage areas.

Regular testing of safety gate mechanisms ensures they operate smoothly and lock securely when required. Springs, hinges, and locking mechanisms require periodic lubrication and adjustment to maintain proper function. Safety signage and load capacity placards should be kept clean and legible, with damaged signs replaced promptly. Training personnel on proper use of safety systems reinforces the importance of following established protocols.

Maintaining clear emergency access routes and egress paths requires ongoing attention to storage practices and equipment placement. Stairways, walkways, and emergency exits must remain unobstructed and well-lit at all times. Regular inspection of emergency lighting systems ensures they will function properly during power outages or emergency situations. Handrails and stair treads should be checked for wear, damage, or accumulation of materials that could create slip hazards.

Emergency communication systems integrated with mezzanine installations require periodic testing to verify proper operation. This includes emergency phones, alarm systems, and visual warning devices that help coordinate evacuation procedures. Maintaining updated emergency response plans and conducting regular drills helps ensure personnel are prepared to respond appropriately during crisis situations.

Protective coatings on mezzanine rack components provide essential defense against corrosion and environmental damage. Regular inspection of paint and galvanized surfaces helps identify areas where protection has been compromised by mechanical damage or normal wear. Touch-up painting should be performed promptly to prevent corrosion from spreading to underlying steel components. Establishing coating maintenance schedules based on environmental conditions and usage patterns helps optimize protection while controlling costs.

Environmental factors such as humidity, temperature fluctuations, and chemical exposure significantly impact coating performance. Facilities with aggressive environments may require more frequent coating renewal or specialized protective systems. Documenting coating application dates and performance history provides valuable data for optimizing maintenance intervals and selecting appropriate materials for future applications.

Maintaining appropriate environmental conditions around mezzanine racks helps preserve structural integrity and extend service life. Temperature control systems should maintain stable conditions to minimize thermal stress and reduce condensation that could promote corrosion. Humidity control becomes particularly important in coastal areas or facilities handling moisture-sensitive products. Adequate ventilation prevents stagnant air conditions that could accelerate deterioration processes.

Seasonal maintenance adjustments account for changing environmental conditions that affect rack performance. Winter preparations might include checking heating systems and ensuring proper drainage to prevent ice formation. Summer preparations focus on cooling system maintenance and monitoring for thermal expansion effects. Regular calibration of environmental monitoring equipment ensures accurate data collection for maintenance decision-making.

Maintaining compliance with applicable building codes and safety regulations requires systematic tracking of inspection results and maintenance activities. Regular reviews of current regulations help identify any changes that might affect existing installations or maintenance procedures. Professional structural inspections by qualified engineers provide independent verification of system condition and compliance status. These assessments become particularly important for older installations that may need upgrades to meet current standards.

Insurance requirements often specify minimum maintenance standards and inspection frequencies for warehouse storage systems. Documenting compliance with these requirements protects against claim denials and demonstrates due diligence in risk management. Regular communication with insurance providers helps ensure maintenance programs meet their specific requirements and take advantage of any premium reductions available for exemplary safety programs.

Comprehensive documentation systems track maintenance activities, inspection results, and repair histories for mezzanine rack installations. Digital record-keeping platforms provide searchable databases that support trend analysis and predictive maintenance strategies. Maintenance logs should include detailed descriptions of work performed, parts replaced, and any observations about system condition or performance. Photographic documentation supplements written records and provides visual evidence of system condition over time.

Establishing standardized documentation procedures ensures consistency across different shifts and maintenance personnel. Training programs for maintenance staff should emphasize the importance of accurate record-keeping and provide guidance on proper documentation techniques. Regular audits of maintenance records help identify gaps in documentation and opportunities for process improvement.

Developing comprehensive preventive maintenance schedules helps minimize unexpected failures while controlling maintenance costs. These schedules should be based on manufacturer recommendations, environmental conditions, and actual usage patterns observed in the facility. Predictive maintenance technologies such as vibration monitoring or thermal imaging can help optimize maintenance timing by identifying developing problems before they require emergency repairs.

Inventory management for maintenance supplies ensures that necessary parts and materials are available when needed without excessive carrying costs. Establishing relationships with qualified suppliers provides access to genuine replacement parts and technical support when needed. Regular review of maintenance costs helps identify opportunities for process improvements or equipment upgrades that could reduce long-term expenses.

Investing in comprehensive training programs for maintenance personnel improves the quality of maintenance work while reducing the risk of damage from improper procedures. Training should cover proper inspection techniques, safety protocols, and documentation requirements specific to mezzanine rack systems. Regular refresher training keeps personnel current with best practices and introduces new techniques or technologies that could improve maintenance effectiveness.

Cross-training maintenance staff on different aspects of rack maintenance provides operational flexibility and ensures continuity of maintenance programs during personnel changes. Developing internal expertise reduces dependence on outside contractors while providing career development opportunities for existing staff. Certification programs for maintenance personnel demonstrate competency and provide recognition for professional development achievements.

Professional structural inspections by qualified engineers should be conducted annually for most mezzanine rack installations, with more frequent inspections recommended for systems operating in harsh environments or carrying maximum load capacities. High-usage facilities may benefit from semi-annual inspections, while installations showing signs of stress or damage require immediate professional evaluation regardless of the normal schedule.

The most frequent maintenance issues include loose connection bolts, damaged protective coatings leading to corrosion, overloading beyond design capacity, and inadequate cleaning leading to debris accumulation. Environmental factors such as moisture exposure and temperature fluctuations can accelerate these problems, making regular inspection and preventive maintenance essential for preserving system integrity and maximizing service life.

The repair versus replacement decision depends on the extent and type of damage, with structural components typically requiring replacement if they show signs of cracking, severe bending, or weld failure. Minor surface damage such as paint scratches can often be repaired through proper cleaning and recoating procedures, but any damage affecting load-bearing capacity should be evaluated by a qualified structural engineer before determining the appropriate course of action.

Safety precautions include implementing lockout/tagout procedures for any mechanical systems, using appropriate fall protection equipment when working at elevation, ensuring adequate lighting in work areas, and maintaining clear communication between maintenance personnel and warehouse operations staff. All maintenance work should be performed by trained personnel using proper tools and following established safety protocols to prevent accidents and ensure work quality.